Bradstone Approved Contractor

Transform your outdoor space with expertly installed paving and landscaping solutions in Hemel Hempstead. M & P Paving Contractors deliver durable, attractive results tailored to your home and style.

Member of Bradstone Approved Installer

M & P Paving Contractors

Investing in a new driveway or patio is a significant decision. As a Bradstone Approved Installer, M & P Paving Contractors deliver block paving installations built to last and designed to add long-term value to your property. Every project follows strict preparation and installation standards, ensuring your driveway or patio is laid on a strong, reliable foundation for lasting quality and durability.

Preparation – our approach to getting your job done

Preparation is the foundation of quality. The success of any paving or driveway installation depends on how well the groundwork is carried out. Careful preparation ensures a solid, durable base that supports the finished surface, preventing future issues and guaranteeing a long-lasting, high-quality result.

Start Your Project with Us

Quality Workmanship You Can Trust

Ready to enhance your home with a new driveway, block paving, resin surface, patio, or professional landscaping? M & P Paving Contractors proudly serve homeowners in Hemel Hempstead, Watford, St Albans, Rickmansworth, Bushey, Berkhamsted, Harrow, and across Hertfordshire towns. Call us today to discuss your project and arrange a free no-obligation quote.

The steps we take

Paving Installation Process

Proper preparation and installation are key to a long-lasting paved area. The process begins by marking and excavating the site to the correct depth and slope, installing drainage and edge restraints, and laying a solid sub-base. Sharp sand is spread and levelled before blocks are carefully positioned, cut where necessary, and compacted. Jointing sand is brushed into gaps, and the area is repeatedly compacted until fully settled, ensuring a durable, even, visually appealing finish.

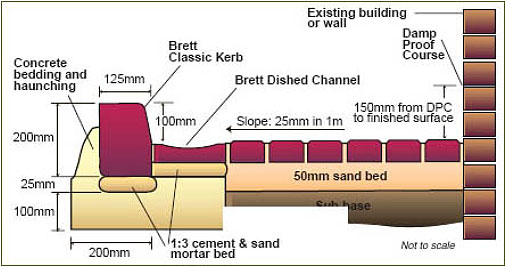

Step 1: Mark out the area to be paved and remove the existing surface to a depth that ensures the finished level sits at least 150mm (approximately two bricks) below the damp-proof course. For proper drainage, create a 1:80 slope during excavation that falls away from any building or fence.

Step 2: Install manhole covers, drainage channels, and edge restraints as required.

Step 3: Fill the excavated area with a minimum of 100mm of sub-base material and compact thoroughly using a plate compactor, filling any voids with sharp sand.

Step 4: Spread 50mm of sharp sand, compact with the plate compactor, then apply a further 15mm of sharp sand as a loose screed and level carefully.

Step 5: Lay a single course of blocks on the sand along all edge restraints.

Step 6: Lay the blocks hand-tight with a joint gap of 2–5mm, starting from one corner and at the base of any slope. Use blocks from at least three different packs to ensure an even colour distribution. Cut blocks at edges with a block cutter, bolster chisel, and club hammer.

Step 7: Sweep the surface thoroughly, especially if a block cutter has been used, and replace any damaged blocks.

Step 8: Compact the entire area with three to four passes of the plate compactor in perpendicular, overlapping directions.

Step 9: Brush jointing sand over the whole area, ensuring it penetrates fully into the joints. Do not apply jointing sand in wet weather, as it will not settle correctly.

Step 10: Refill any gaps that appear in the joints and compact again. Repeat until all joints are solid and leave surplus sand to be naturally washed in by wind and rain as the paving settles.